South Canterbury farmers Hamish and Fiona Winter have a stellar track record for their herd’s reproduction performance, with a key highlight being an 81% 6-week in-calf rate, surpassing the industry target of 78%.

When it comes to milk production, their aim is for the cows to do 100 kgs more than their body weight – around 575 kg/ms each.

“Last year we did 582 kg/ms per cow,” Fiona says. “If we got there every year, we’d be very happy.”

They share some of their key management practices that help them consistently achieve these impressive results.

Farm Facts

Business Type: Owner-operator (with 1.5 staff)

Location: Morven, Waimate, South Canterbury

Farm Size: 88ha

Peak Cows: 385 (FJX) Winter no more than 400

PSC: 1 August MA Cows, 24 July R2 Heifers

Stocking Rate: 4.4 cows per ha

Farm System: System 5

Herd BW average: 294

Herd PW average: 324

Breed average: F9J7

Liveweight BV average: 1.8

Production: 220,000 kgMS/year budgeted, 2,500 kgMS/ha, 571 kgMS/cow. 2022/23 season 224,067 kgMS.

Production (3 year average): 563 kgMS/cow and 2,464 kgMS/ha

Repro overview

Hamish and Fiona put collars on their cows three seasons ago and haven’t looked back.

“The AI technician from the year before, put collars on his own cows,” Hamish recalls. “He put the collars on really late so he had to do scratchies as well. I ran into him and he showed me a scratchie that was completely untouched and asked me if I’d mate that cow. I said, ‘no, probably not’. And he goes, ‘the collars told me that this cow was on heat, and she was absolutely 100% on heat when I did it’.”

“So that kind of converted us to the collars,” Fiona adds. “You're always going to get the phantom cows. So that's what we said – ‘well, there's one of your phantoms you would never have got’.”

Before collars, tail paint was used for heat detection.

“Every morning milking I was doing heat detection,” Hamish says.

“When I redid their tail paint after they were inseminated, I would write the day of AI in the middle of their back, right up the front, so that the next morning if you saw she'd been ridden again, you’d know that was yesterday. It worked well but that was me every day for seven weeks, which is a lot.

“Now with collars, it's just so much less workload,” Hamish says. “We've got a pretty standard CIDR system. We stick a bunch of early CIDRs in before the planned start of mating so that we mate them on day three. Then we have another two drafts of CIDR. On day 24, anything that hasn't been mated gets drafted out.

“As soon as we put collars on, that was also the end of having any bulls on this farm, which I don't miss at all.”

As soon as the cows calve mating becomes a focus, says Fiona.

“It's about getting her back. It's about getting her pumping, recovering from the calving and putting milk in the vat and getting her in good condition and cycling again to get back in-calf as fast as possible.”

Hamish says easing the cows back into milking also reduced the herd’s mortality rate.

“When we changed to once a day in our colostrums, our colostrum cows stopped dying, which was good because that was where most of our spring deaths used to be, in the colostrums and not in the springers.”

When it comes to their mating plan, Fiona says they stick to what they know works for their herd.

“We mate the bottom 15% to Hereford for the first three or four weeks, followed by short gestation. Everything else gets mated to Daughter Proven.”

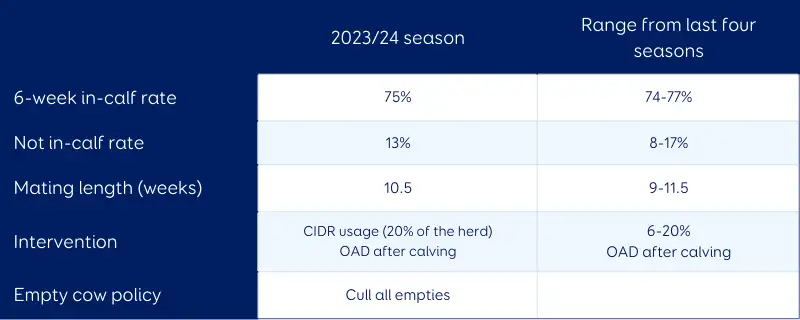

“Every season our goal is to try and get every cow in-calf as soon as possible. We aim for a six-week in-calf rate of higher than 75%, and in a perfect world, we'd like less than 9% empties.”

This ‘keep it simple’ mentality flows through to how they utilise their herd’s collars too.

“There’s a lot of data on the collars that we don't use.” Fiona says. “We don’t look at individual rumination. We will check the herd’s average rumination, but that's as far as it'll go.”

It’s just not practical for the farm, Hamish says.

“The problem here is it's 400 cows. There's one worker and a relief milker so when you start making more mobs, it gets really tricky, really quick.”

“We try not to make things too complicated and too hard,” Fiona says. “So if a cow was unwell or something like that, by all means, she'll stay in the once a day herd for a long time until we're happy with her.”

To try and get a more even mob of replacement calves, Hamish and Fiona increase the weaning weight every two weeks.

“I’ll start off at a certain weight, say 84kg, then two weeks later I’ll add two kgs,” Fiona explains.

“It makes sense because your bigger ones will always be bigger but if you don’t let the younger ones catch up, they never will. I’m constantly moving the target so by the end we try and have them all even.”

Hamish believes having fully fed cows is largely responsible for their impressive repro results and milk production.

“Most operations could produce like we do if they were prepared to feed like we do.

“Every day of the year, whether that be in December, whether that be in March, or whether that be in June, our cows are fully fed. That's a big driver of why we manage to get them in-calf is because they're always fat, they're always fed well. And that's always been the way we've farmed from when we started.”

“We've been farming for 15-16 years, and I'm still interested in learning,” Fiona says.

When it comes to looking for advice, Hamish and Fiona use a number of different avenues, including Facebook, Google and their local vets.

“You’ve got to take it where you can get it,” Hamish says. “But you've got to be able to prove it to yourself before you implement it too.”

Fiona says thinking critically is key. “You need to ask yourself; will it work for you? Farming in the North Island is different to farming in Canterbury. Everything's different. But the biggest thing is not thinking you know it all.”