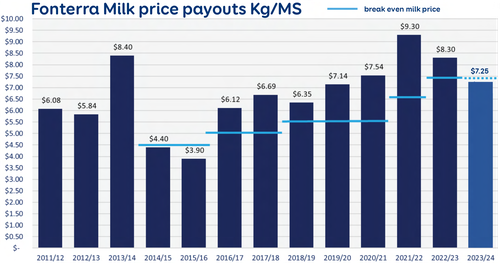

The challenges faced by farmers in today’s dairy sector are perhaps like nothing faced before: despite relatively high milk payouts of recent years, profits are ironically shrinking due to skyrocketing costs related to the production of milksolids.

The last few years have seen climbing costs of fertilizer and labour as well as fuel, feed, freight, and interest rates.

With many costs outside farmers’ control, it’s becoming harder for some farmers to find places to manage the cost of production on farm.

Meanwhile, regulations are also having a large impact: the reduction in nitrogen use to 190 KgN/ha has led to an inevitable squeeze on the potential of dry matter per hectare produced on farm. This prompts a reduction in the number of cows milked, and in many cases total milk production.

Additional compliance costs for environmental plans, wintering consents, and so on, also continue to increase. In the 2014-2015 milk payout drop, much of the industry learned a valuable lesson in how to reduce or maintain low cost of production on farm. The potential to further reduce costs is not as great as it once was.

How do we get back to a profitable scenario?

For many, the key is to be more efficient in the way milk is produced. Efficiency could be summarised as reaching the peak level of performance through use of the fewest inputs, while achieving the highest possible output.

In simple terms, more milk from less.

Overall farm efficiency can be improved by incorporating technology such as wearables, automatic drafting gates, and automatic cup removers (ACRs). This helps improve milking efficiency, and generally means fewer mastitis treatments, for example. In addition, this kind of technology means cow sheds can often be run by one labour unit. Other advantages include accurate and reliable heat detection and fewer health issues.

Of course, affordability within a financial budget is key, with debt increasing significantly over recent years across some dairy farms.

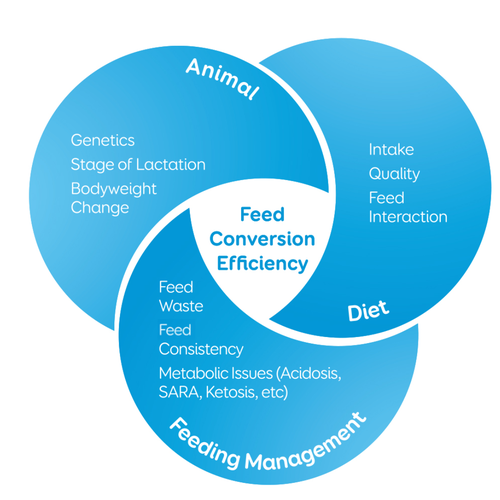

Whether your farm operates in a system 1 or a system 5, increasing Feed Conversion Efficiency (FCE) will make the whole dairy farm system more efficient.

By seriously measuring, monitoring, and taking action on all factors directly affecting FCE, the same, or more, milk using less feed is the fundamental outcome.

FCE can be increased by measuring and acting on a day-to-day basis on existing data available on farm already. This data enables informed decisions designed to improve profitability. FCE is determined by animal, diet, and management components.

Animal component

Body Condition Score (BCS) is a key driver for FCE. If the animal reaches, or maintains, ideal BCS along the lactation and dry periods, cows are likely to perform at their full potential. In addition, high genomic breeding worth (gBW) and production worth (PW) cows will have a better chance of producing more milk than low gBW/PW cows.

Dietary component

A balanced diet with quality feed positively impacts FCE, as the cows will have higher intakes and fewer wasted nutrients. Higher intakes result in higher FCE, which equates to better profit margins. Be accurate. Use average MjME values for the feed, or test your own feed. Total MjME intake will be different in either scenario. Is the measure ‘feed offered’ or ‘feed consumed’? All these will have an impact on feed intake, consequently affecting FCE.

Feeding management component

Feed waste is the most common factor that negatively affects feed conversion efficiency. Feed waste can reach as high as 30-40% in extreme cases. It’s well-known that the most profitable farmers not only grow more grass, but utilise a high percentage of that grass they grow.

Waste not only occurs in the paddock, but also on feed-pads, in-shed feeding systems, through estimations of how much the feed wagon load weighs, or through ‘guessing’ the silage DM percent rather than testing.

Feed allocation has a positive correlation with FCE too. Consistency of feeding in a pasture-based system is hard to achieve but by no means impossible, and farmers should aim for it.

Metabolic issues also have a negative impact on FCE. As some of these metabolic issues (ketosis, sub-acute rumen acidosis) are hard to measure on farms that aren’t using collars, more attention must be paid on prevention strategies.

On many farms, information already exists, and is ready to be used.

Farmers should understand what’s important to measure, and why. Having accurate, realistic, data enables informed decisions.

Measuring, monitoring, and responding can help result in a resilient, sustainable, and profitable dairy business. Not all farms will share the same room for improvements in terms of feed managment, but good can only come from taking a look at your own farm’s scenario.

Take time to investigate this season!