Southland couple Michael and Fiona O’Hare own seven farms throughout the region, but when it comes to reproduction it’s their 224ha Foxhall dairy block near Invercargill that’s the stand-out from which other farms can model themselves on.

Foxhall was converted to a dairy operation in 2015, and herd numbers have gradually increased since that time.

Now that Michael is comfortable with cow numbers (717 peak cow numbers), today the focus is squarely on improving herd quality and efficiency.

And rather than relying on large-scale investment in technology, the couple’s strategy for improvement rests on a conveyor belt of well-grown quality replacement heifers, the continued dedication of key staff, and superior repro results.

Foxhall is a classic example of a farm that focuses on the fundamentals of balancing production with reproduction.

While maintaining annual production at 337,000 kg milksolids (468 kg MS/cow/year) during the past several years, the farm’s six week in-calf rate has ranged between 75% and 82%, with a not-in-calf rate of between 9% and 11% (significantly better that the regional averages of 70% and 14% respectively).

How do they do it?

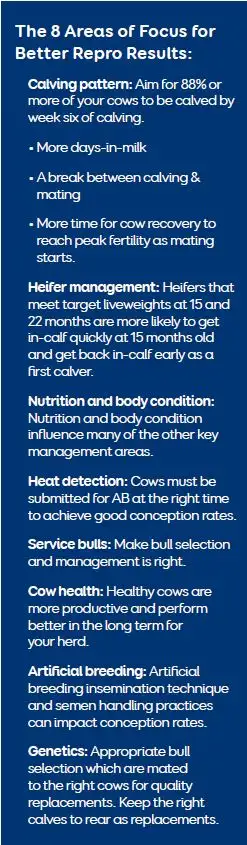

There are eight major focus areas for reproductive improvement, and although Foxhall pays attention to all areas (to some degree), it’s a focus on 3-4 disciplines in particular that appears to set up the herd for continued success.

- Accurate heat detection and highly-engaged staff;

- Nutrition and Body Condition Score(BCS);

- Young stock/heifer management, and;

- Bull power.

Accurate heat detection involving highly-engaged staff

Michael says the farm has a simple mating plan: Artificial breeding (AB) takes place in the first six weeks of mating using Premier Sires Forward Pack, ensuring a mix of young genomically-selected bulls and daughter proven sires are mated to all on-heat cows.

After the AB period, natural-mate Jersey bulls are introduced to the herd for four weeks, and once mating is finished, cows identified as still not-incalf leave the farm as soon as practical.

More recently, scratchies for the first and second round have been used in conjunction with tailpaint, but that wasn’t necessarily the key to great submission and conception rates, Michael says.

“You need the right people on the ground that are capable and have a desire to succeed.”

In the first six years of Foxhall’s operation, Ven, (a Filipino farm manager/contract milker) took it upon himself to be the main observer and ‘picker of heats’, says Michael.

“He stood on the stand himself, and he did that every day for the first six weeks (the AB period). He wanted to learn, he was driven, and he got to know the herd, and every year he just got better and better. He had great attention to detail.

“We’ve since employed another Filipino guy, little Mike, and he’s taken over on Foxhall but they continue to learn and challenge one another. They make a real effort to get the cows in-calf, and they’ve proved themselves.”

In the lead-up to planned start-of-mating, cows are given every chance to start their cycling (the farm does not use CIDRs).

The entire herd is metri-checked. Blood samples are also taken from the herd to check for mineral deficiencies, with shortfalls addressed through Dosatron.

What also makes a difference is that Mark Bennett, LIC agri manager, turns up prior to AB with several MINDA reports from which learnings are taken from the previous season.

Mark briefs the staff on where improvements can be made, and provides material that helps staff in what to look for when identifying cows on-heat.

Feed is King: Nutrition, Weight Monitoring, and Body Condition Score

Repro begins from the day a replacement calf is born.

“The farm policy is that the calves aren’t allowed to leave the dairy farm until they’re 100kg, so it’s up to the contract milker to get them there.”

As the calves are given a good start at Foxhall, the body condition score of the milking herd post-calving is carefully monitored by Michael and ‘Little Mike’ (contract milker Mike Pelesco).

“Before mating if light and not cycling, we put them on once-a-day (milking) ” says Michael. “And to me that’s a game-changer. You might sacrifice a little bit of production, but you get them back-in-calf.”

Cows are also well-fed to bring them back to condition in time for mating (4.5 for heifers, 4.0 for cows).

A mixture of palm kernel, distillers dried grains (DDG), silage, and pasture is provided to ensure cows are on a rising plane of nutrition heading into mating.

“If there’s a shortage, I like to know there’s plenty of surplus silage and feed lying around the place to fall back on,” Michael says.

“I’d rather have it sitting there than go looking for it when it’s needed. We try not to have a hungry animal or a feed shortage before we act. We like to act well before we run out.”

Young stock/heifer management

Once they reach their target 100kg weight at Foxhall, replacement calves head off the main dairy farm.

In 2018, Michael and Fiona purchased an 1162ha run-off at Wyndham to serve their multiple dairy farms.

When they arrive at Wyndham, replacement calves from farms across the wider business are graded according to their weight classes, “so the competition for feed is kept as even as possible,” Michael says.

The calves are weighed at least 3-4 times in their first year, then 2-3 times as rising two-year-olds. At 15 months of age, the calves are naturally mated to Jersey bulls to ensure the first calving is relatively easy.

When they’re ready for the milking platform, the replacements arrive back at Foxhall at their mature weight, averaging 530kg, “so they hit the ground running from there.”

Michael describes getting the heifers to proper condition as “a game changer” for the herd in that it secures a good future in terms of both production and reproduction.

Bull Power

Before being purchased, selected young Jersey (natural-mate) bulls are tested for BVD and EBL, and arrive at Wyndham one year ahead of mating where they are left to graze and mature.

“We buy them as R2s at the end of mating,” Michael says.

“When it comes to mating the heifers at Wyndham, the bulls will have been there nearly a year. We put the bigger bulls out (with the R2s) for the first three weeks. Then we pull those bigger bulls out and they get rested before they go off to the dairy farm, and they’re replaced by the smaller bulls.”

At the main dairy farm, the bull ratio is 1 to every 20 cows yet to conceive.

“They’ll arrive at the end of the first round of AB, about 20 November, so they get a few weeks rest.”

Once their work begins, the bulls are rotated regularly to ensure they are fresh, keen, and healthy.